In industrial machinery and applications, reducing vibrations is crucial for optimal performance and minimizing potential damage. Certain machines generate vibrations during operation, while others are highly sensitive to vibrations from their environment. To address these challenges, the use of spring elements and spring damper elements provides tailored solutions for vibration isolation. Let’s explore the applications, operating principles, and product features of these elements in industrial settings.

Spring elements find applications in various scenarios, including the vibration-isolated installation of machinery in power plants (e.g., turbines, pumps, blowers, coal mills) and large machines such as presses, forging hammers, and crushers. These elements can also be utilized for vibration isolation in buildings or precision machinery, protecting sensitive equipment from environmental vibrations.

By employing vibration isolation through spring elements, the transmission of dynamic loads between machines and their foundations is significantly reduced. Source isolation effectively decreases vibrations generated by crushers or presses, while receiver isolation safeguards sensitive measuring and production machines from vibrations in the surrounding environment.

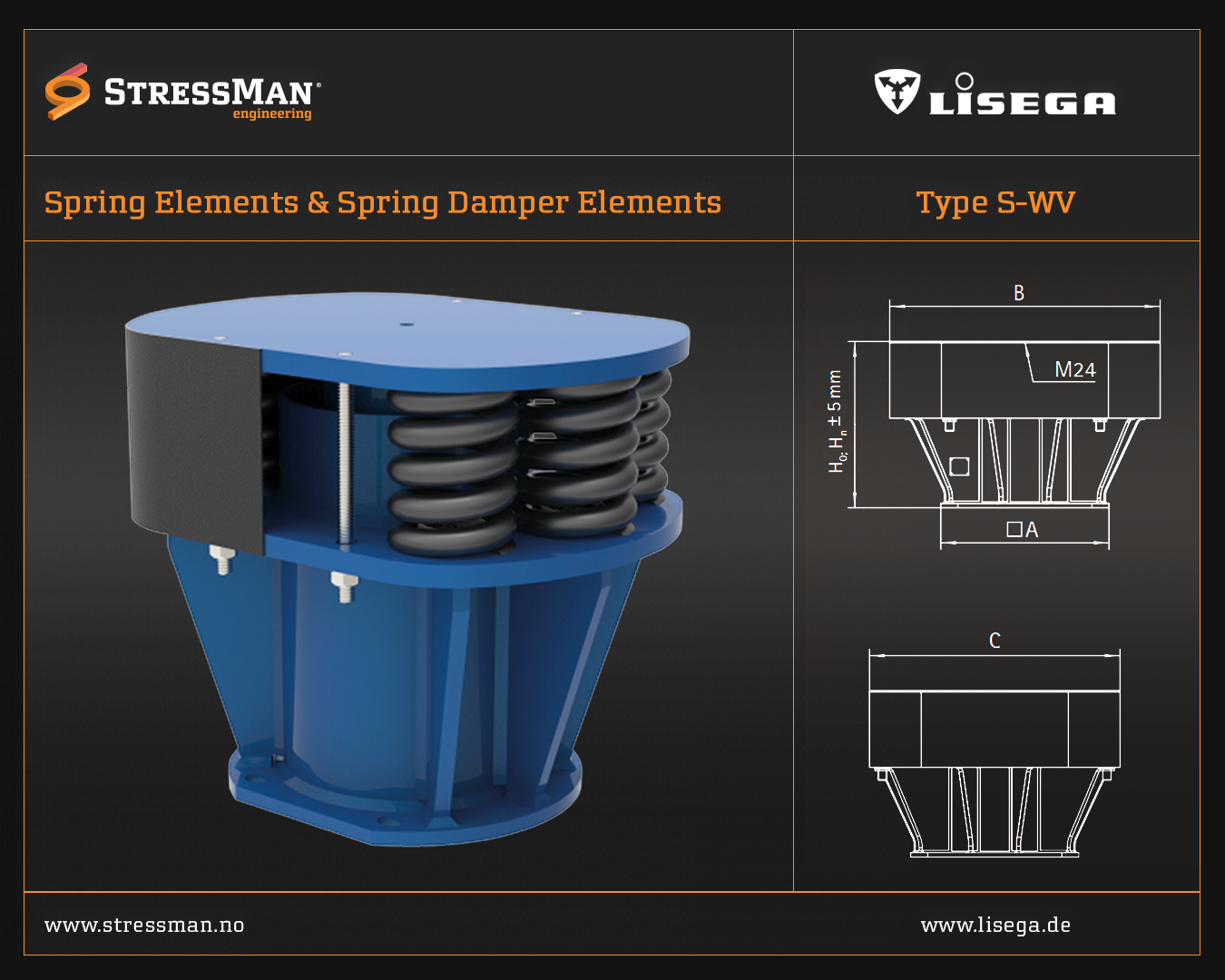

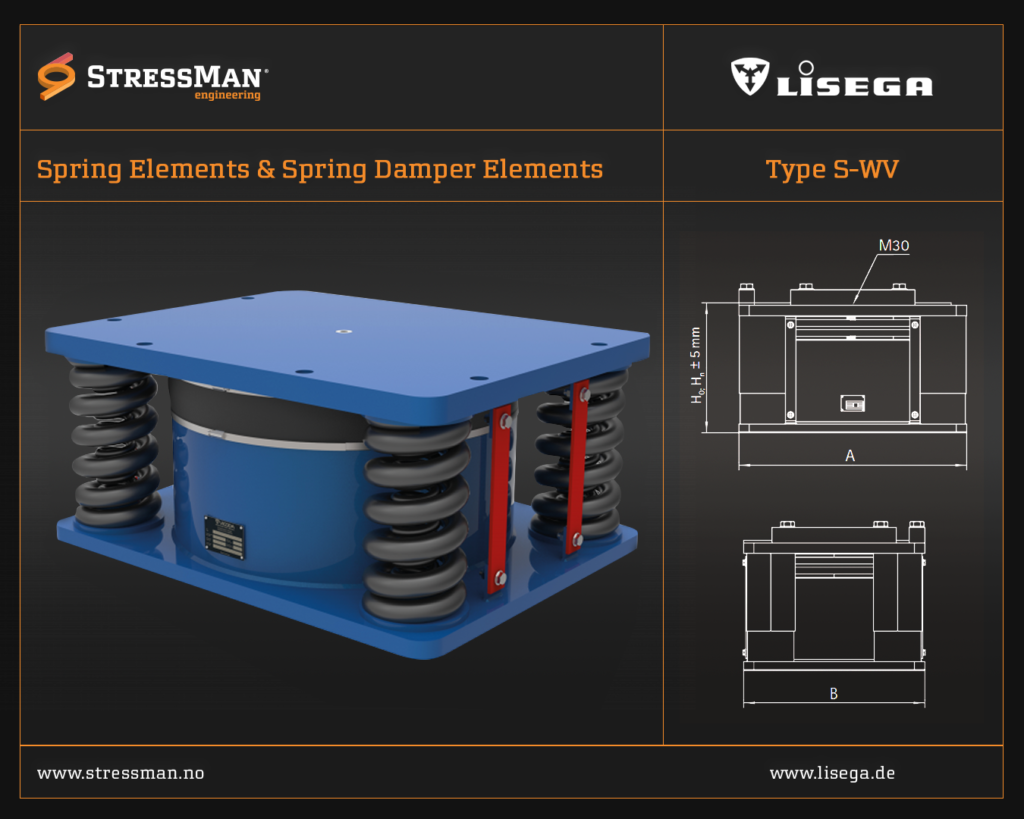

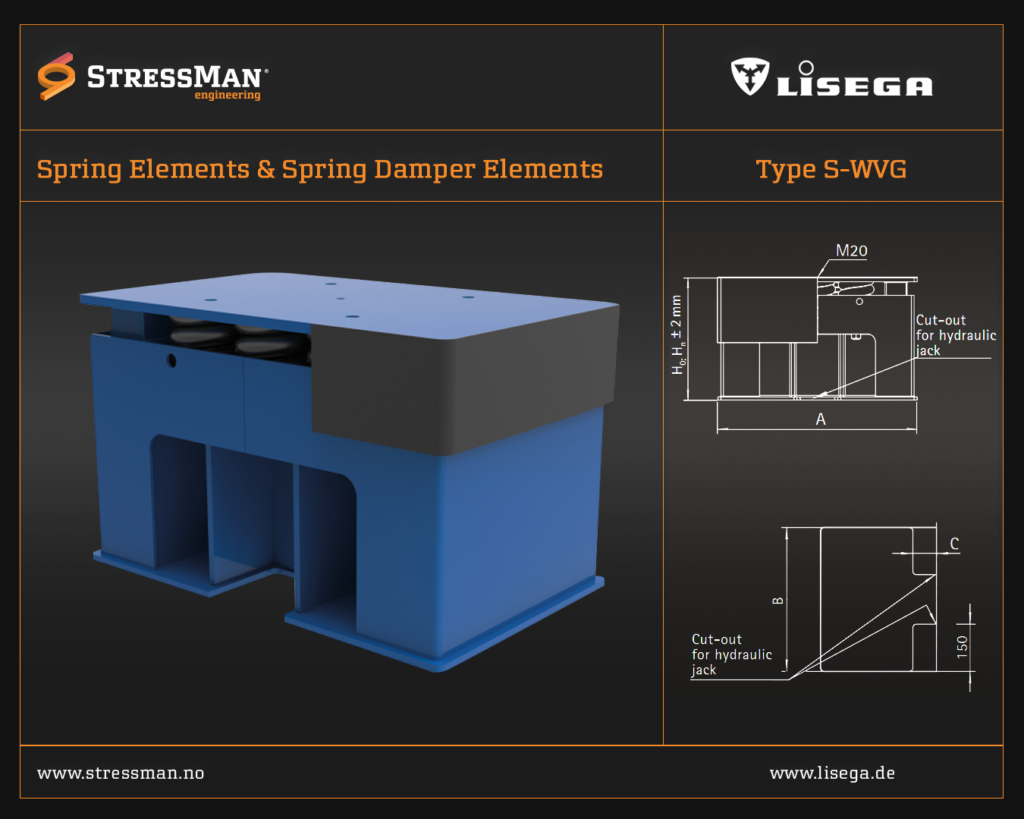

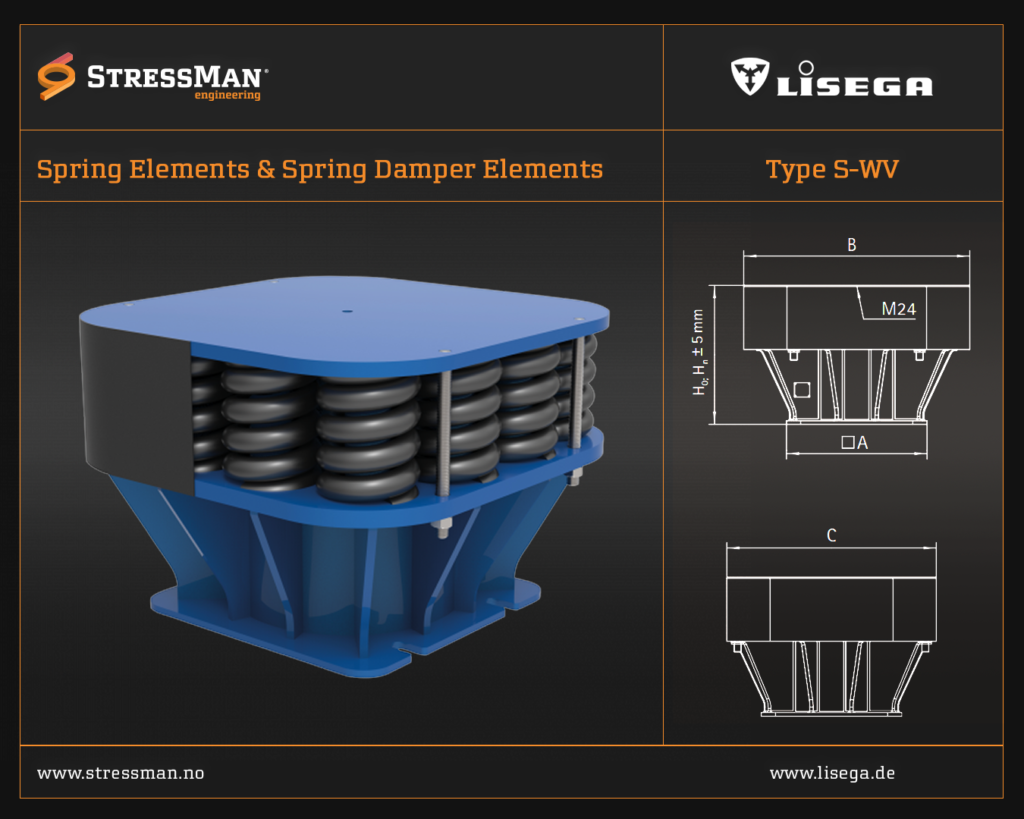

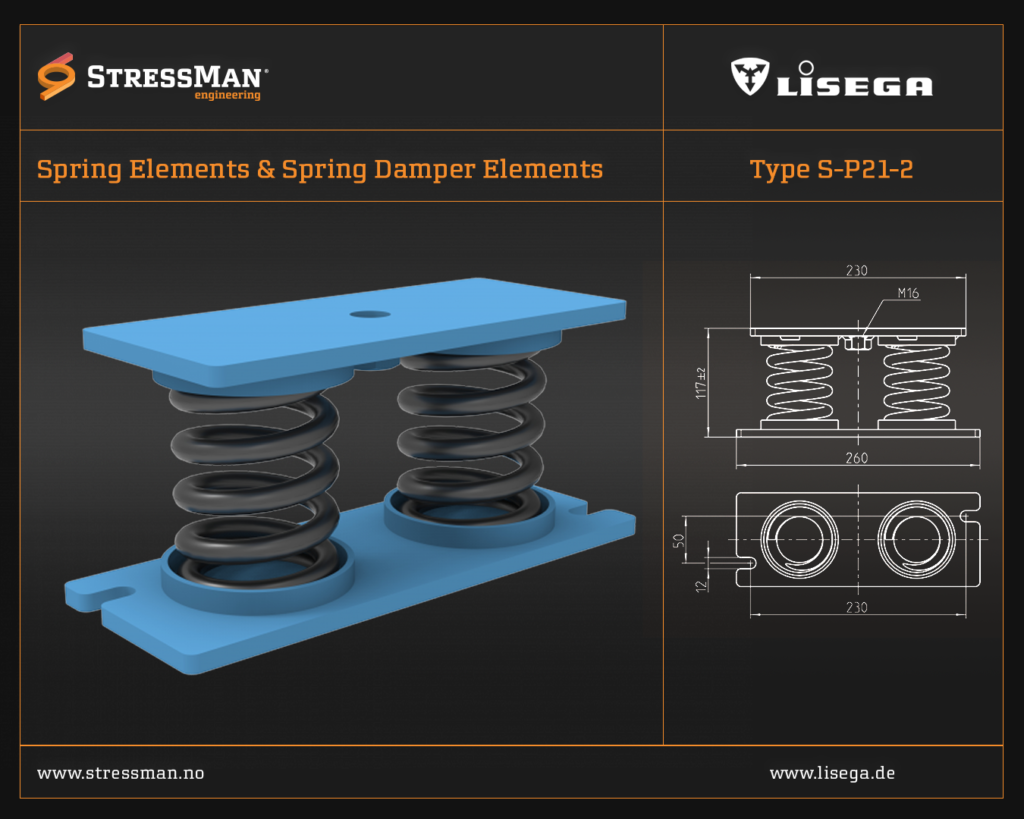

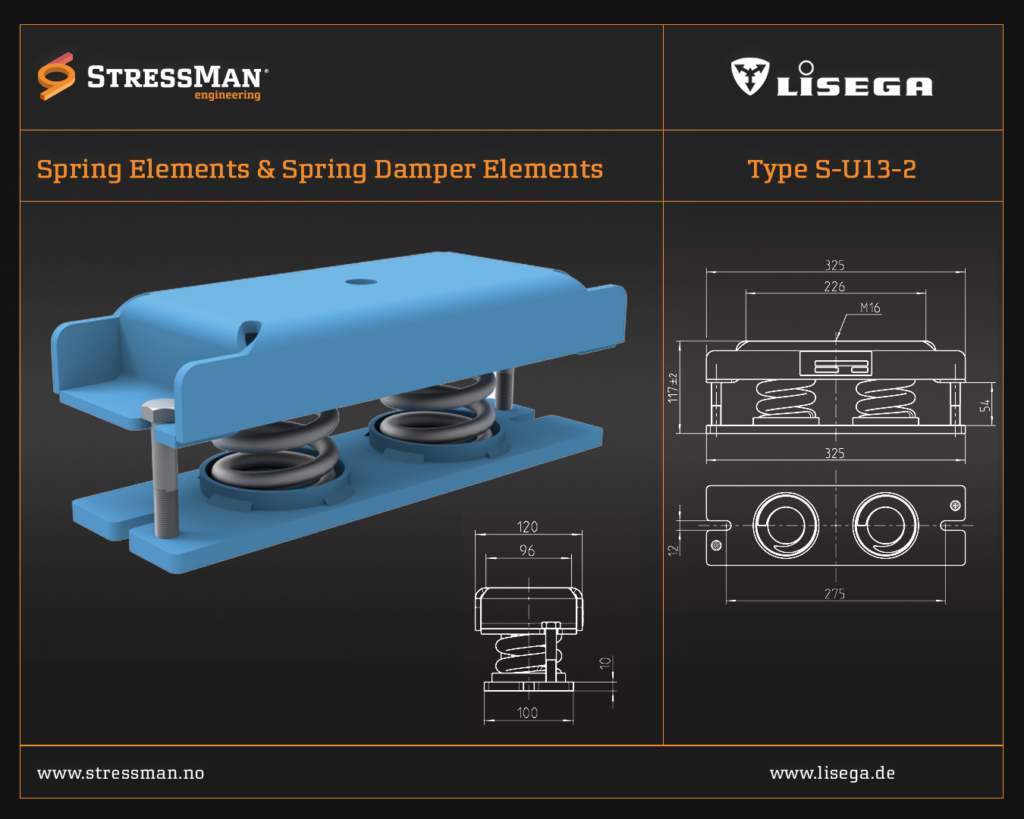

LISEGA Product Features:

- Large Load Range: Spring elements are available in a wide load range, accommodating applications ranging from 1 kN (224.81 lbf) to 2,700 kN (606,984.15 lbf).

- Operational Stability: Compliant with EC 3 regulations, ensuring reliable performance and adherence to industry standards.

- Low Natural Frequency: The system’s low natural frequency, typically between 1 Hz and 8 Hz, maximizes isolation capabilities.

- Horizontal and Vertical Spring Rates: Spring elements offer adjustable horizontal spring rates ranging from 20% to 130% of the vertical spring rate, allowing flexibility in different orientations.

- Preset and Blocked Option: Elements can be preset and blocked, ensuring a readily available replacement whenever required.

- Corrosion Resistance: Surface coatings are available to meet corrosion categories up to C5, complying with DIN EN ISO 12944 standards.

- Integrated Dampers: Spring elements can be equipped with integrated viscoelastic dampers, providing additional damping as needed for specific applications.

Spring elements and spring damper elements play a vital role in reducing vibrations and ensuring the smooth operation of machinery in industrial settings. With their wide load range, operational stability, adjustable spring rates, and corrosion resistance, these elements provide effective vibration isolation for various applications. By employing these tailored solutions, industries can enhance performance, protect sensitive equipment, and minimize the potential damage caused by vibrations in their operations.

For training, presentations, or quotes, contact Juan Manuel Mendez Franco.

Relax, let us handle your stress!