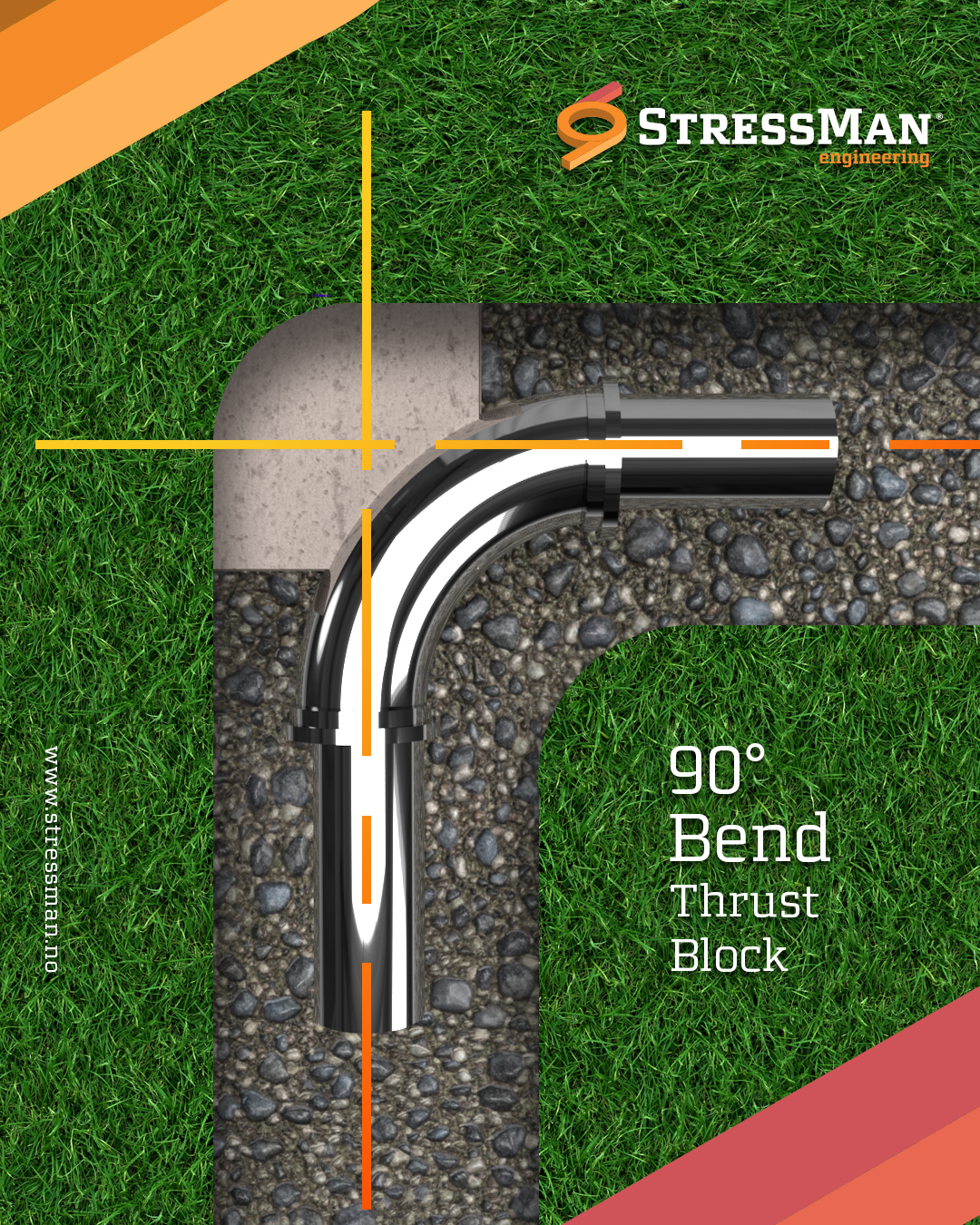

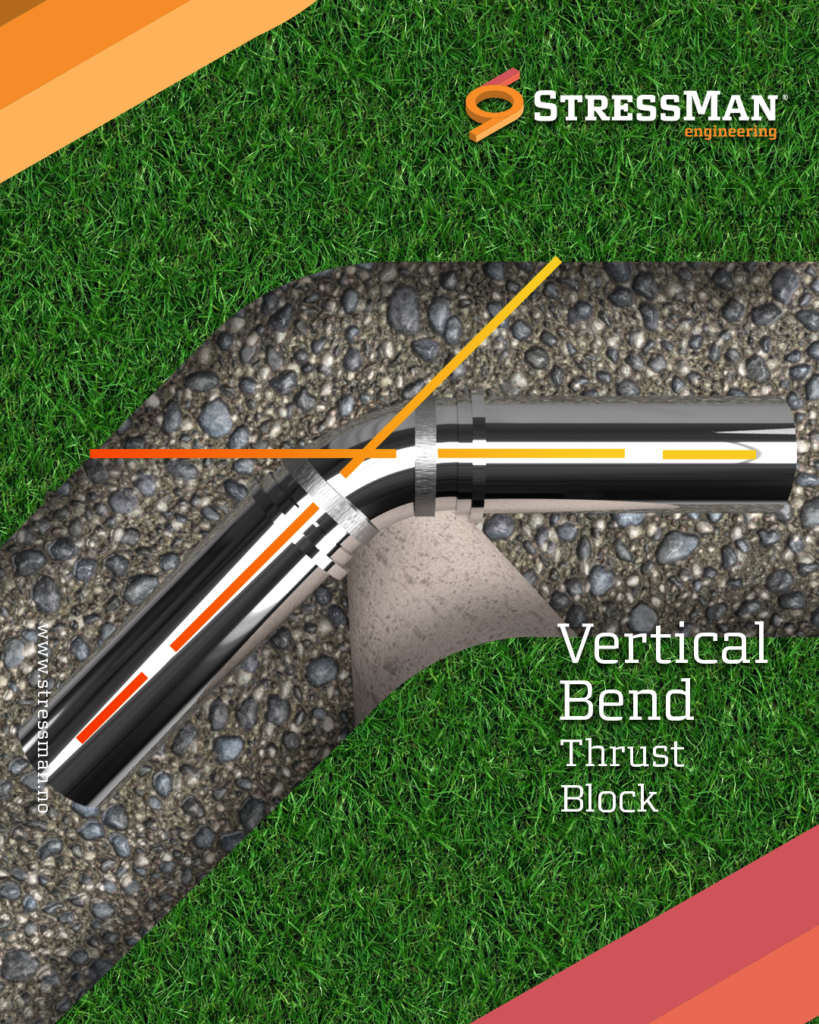

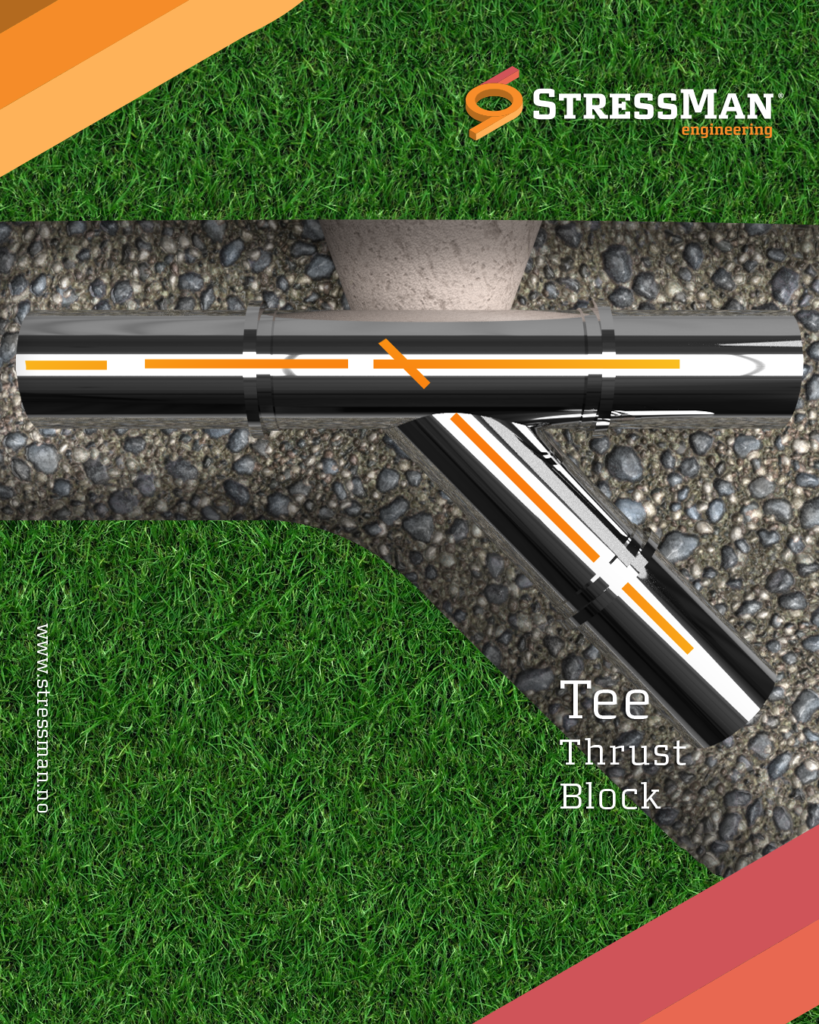

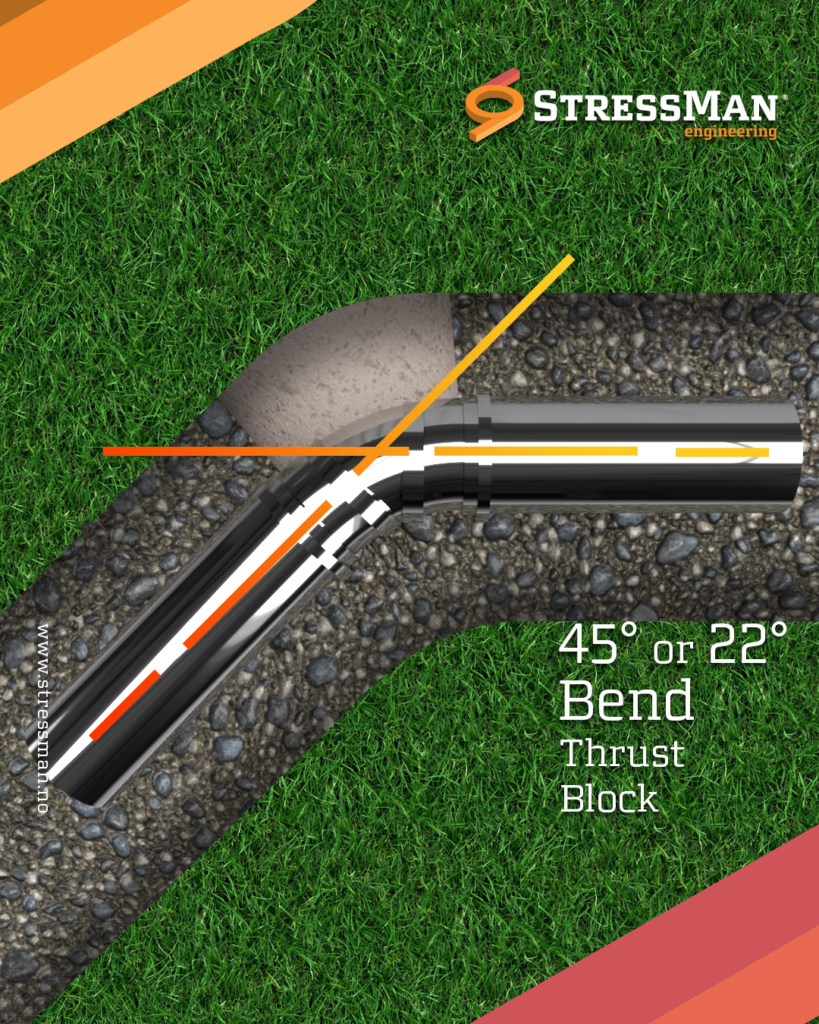

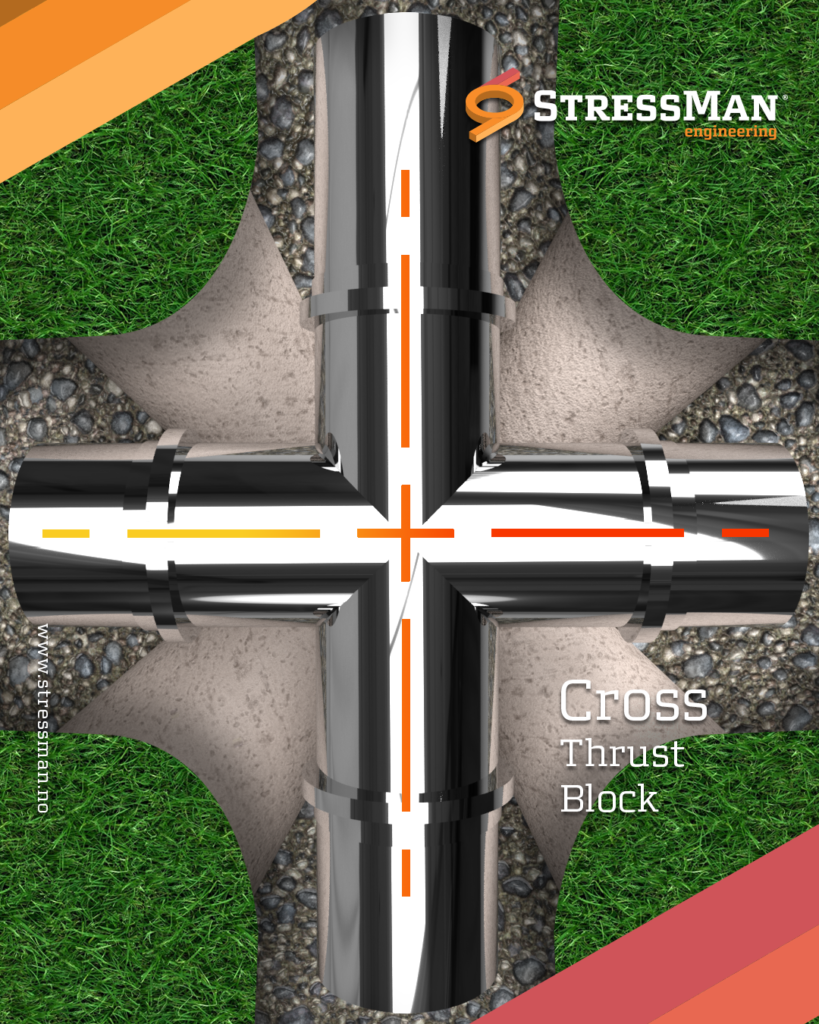

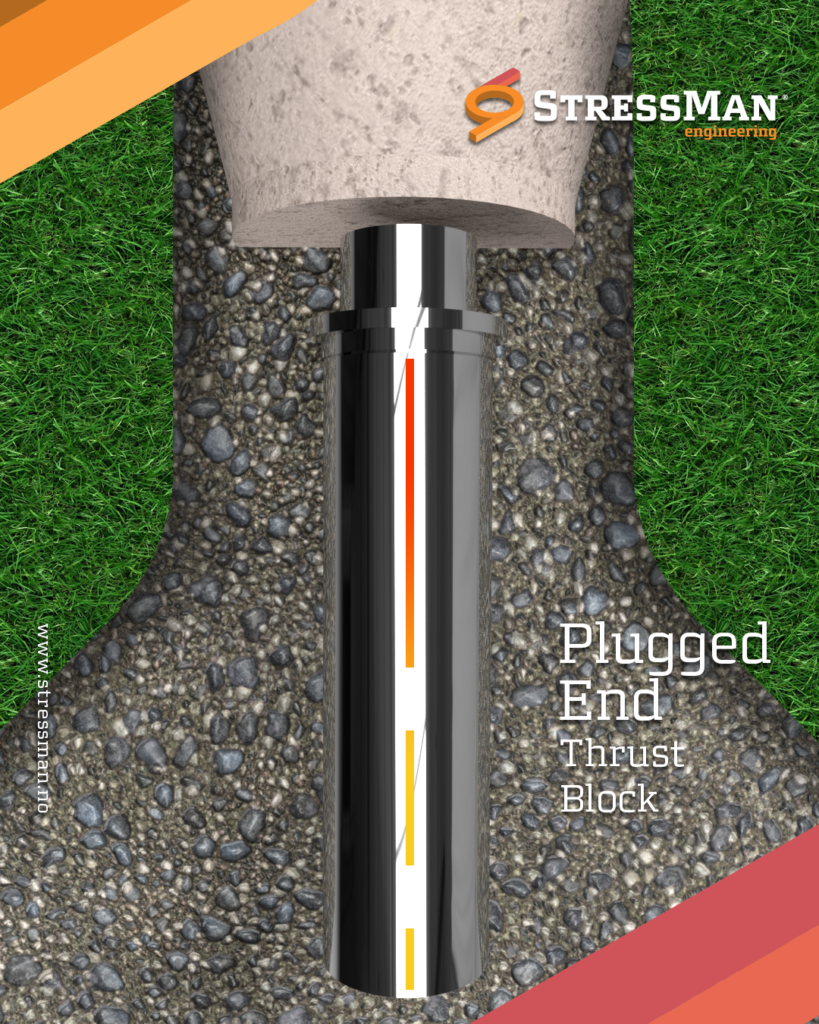

Thrust blocks prevent buried piping from moving when pressure and thermal load are applied. In effect, thrust blocks transfer the load from the pipe to a wider load-bearing surface. Thrust blocks are required where fittings are used to change the direction (i.e., at ties, elbows, wyes, caps, valves, hydrants, and reducers) of buried piping systems.

Determining size and type of thrust blocks

The size and type of thrust blocks depend on pipe size, line pressure & temperature, type of fitting, degree of bend, and type of soil. In most cases, the size and type of thrust block must be determined by the engineer through a detailed piping stress analysis and check of soil bearing capacity.

If the size of the thrust block has not been specified by the engineer, it might be calculated by dividing the total thrust force by the bearing strength of the soil. This gives the square feet of the area needed.

The engineer is the responsible person for determining safe bearing loads (lbs. per square foot) and if doubt exists, soil bearing tests should be run.

Construction of thrust blocks

Thrust blocks are anchors placed between pipe or fittings and a solid trench wall. They can be constructed from available lumber if braced properly. However, the recommended thrust blocks are made with concrete which is calculated to have compressive stress of 2,000 pounds per square inch.

Thrust blocks should be constructed so the bearing surface is in direct line with the major force created by the pipe or fitting and making sure that the earth bearing surface on the opposite side is undisturbed. Thrust blocks can have different shapes, but generally, the simplest form to accomplish the job is required.

In partnership with EngineeringTrainer.com we are pleased to invite you to join our brand new training:

Pipe Stress Fundamentals I & II by Stressman Engineering Online Training Live Session Courses.This training will give you a strong base, solid understanding of Pipe Stress Engineering, help you solve calculations more efficiently, enhance your skills, and allow you to engage in technical discussions with colleagues, vendors, and clients.

Save your spot here: