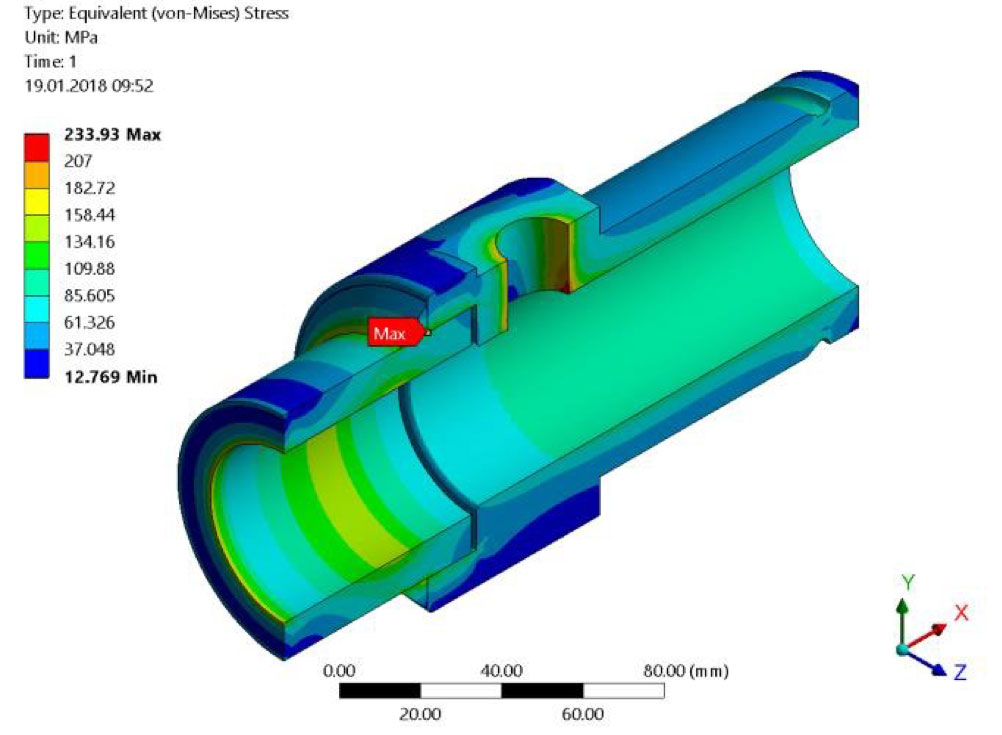

Adaptor Fitting in accordance with ASME VIII division 2

The aim of this project was to evaluate the stresses in an adaptor fitting made of stainless steel 316L. The stresses in the threads were calculated based on hand calculations. The stresses in the fitting was calculated based on finite element analyses (FEA). SCLs are drawn through the areas with the highest stresses. Several locations […]

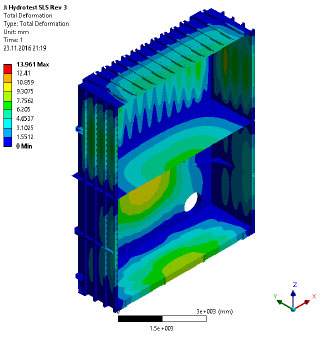

Atmospheric tank calculation

The water tank shown below was analyzed with ANSYS Enterprise Mechanical. Load factors and acceptance criterions was taken from Eurocode and NORSOK. The hydro testing case uses an overpressure of 0.01bar (1m water) in addition to the hydrostatic water pressure and weight. The hydro testing analysis did also include 50% of 100 year return period […]

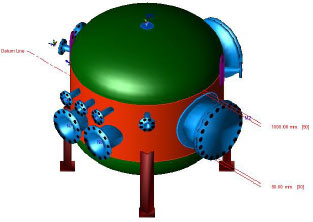

Pressure vessel calculation – ASME VIII Division 1

The pressure vessel shown was analyzed in accordance with ASME VIII Division 1 (2015-edition). Local nozzle calculations was performed with WRC537 (also known as WRC107). All calculations and analyses are done by using the software PVElite from Intergraph. The software uses the Design-By-Rules approach. The maximum allowable working pressure (MAWP) of the shell and heads […]

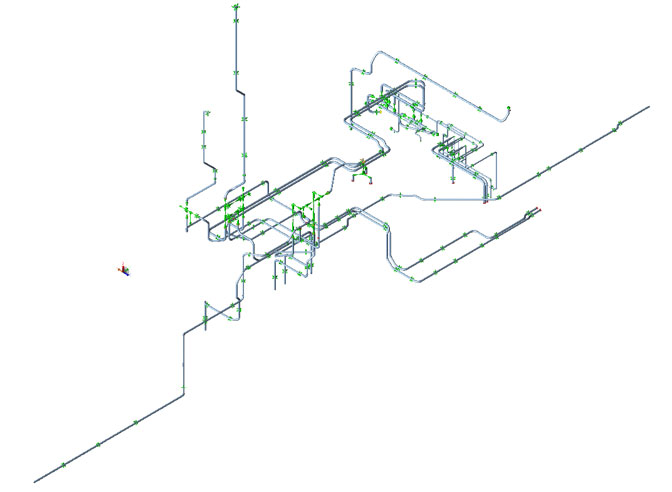

Pulsation analysis of HP drilling system

Team Stressman was engaged to assist a client with a vibrating piping system. During testing of the high pressure (HP) mud pumps, some of the piping near the pumps was shaking. The reason for the shaking was due to pressure pulsations from the HP manifolds was hitting the natural frequency of the piping system. Stressman […]

Complete package calculation of subsea SSIV

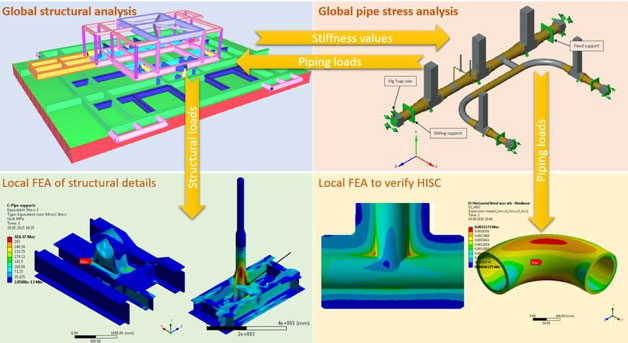

The picture below shows how Team Stressman enjoy working. In the project below, we had the responsibility to perform all the mechanical stress calculations of a complete subsea SSIV. We performed the global structural calculations in SAP2000, the global pipe stress analysis in Triflex, and the local analyses of structural and piping components with ANSYS […]

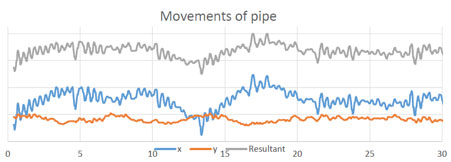

Investigation of Slugging

Vibrations was observed on an installation and an analysis was performed to determine the likelihood of fatigue failure. Team Stressman was sent measurements and video. The motion was due to slugging in the pipe. Based on this input we investigated dynamical stresses. These stresses were checked against DNVGL-RP-0005 fatigue curves, design life factors and stress […]

Subsea Manifold

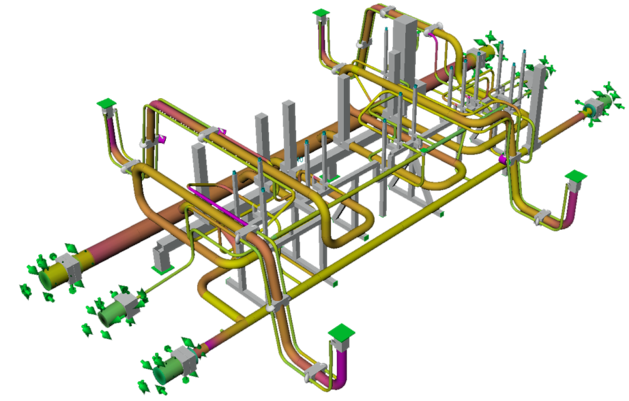

Team Stressman has over the years been chosen to perform flexibility calculations of fast-track subsea manifolds for TechnipFMC. Our responsibility was to verify the structural integrity of the piping and piping components of the subsea manifolds. Subsea piping made of super duplex is exposed to hydrogen induced stress cracking (HISC). This complicates the pipe stress […]

High pressure drilling manifolds

Team Stressman have performed several pipe and structural stress analyses of high pressure (HP) mud, cement and choke & kill manifolds. The pipe and structural stress in the mud, cement and the C&K manifold was calculated for an offshore drilling unit equipment supplier. As we like to look at the tasks from a system perspective, […]