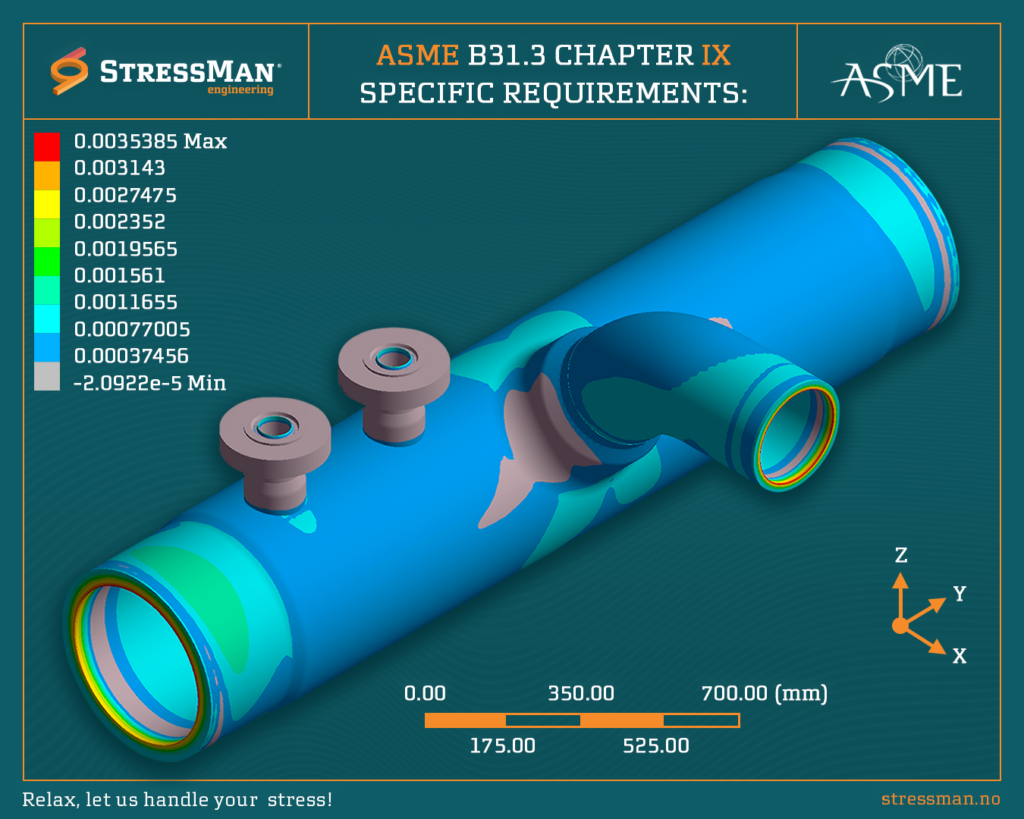

Understanding ASME B31.3 Chapter IX Requirements

In the realm of engineering and design, adherence to standards is paramount for ensuring safety and efficiency. Let’s delve into the specific requirements outlined in ASME B31.3 Chapter IX, shedding light on key considerations for high-pressure fluid service systems:

– System Specification: Owners must designate systems as “High Pressure Fluid Service,” optimizing for safety and performance.

– Material Optimization: While implementing these standards can yield material savings, it’s crucial to acknowledge the associated engineering, examination, and testing costs.

– Allowable Stresses: Higher allowable stresses are permitted, optimizing material use and supporting cost-effective designs.

– Fatigue Evaluation: Mandatory fatigue evaluation ensures longevity and reliability, aligning with ASME Section VIII Division 3 standards.

– Expansion Stress Range: Notably, there’s no 20ksi limit on allowable stresses for expansion stress range, offering flexibility in design. Equation (1b) is not permitted, ensuring adherence to stringent standards.

– Occasional Stress Limits: The limit for occasional allowable stress is reduced, ensuring a conservative approach to design.

– Impact Testing: Rigorous impact testing is required for materials and welds exceeding specified stress thresholds, bolstering safety measures across varied conditions.

– Minimum Design Temperature: Design temperatures are dictated by satisfactory impact test results, guaranteeing resilience under extreme conditions.

– Wall Thickness Equations: The use of limit load pressure-based equations for wall thickness ensures suitability for low D/t ratios, optimizing structural integrity.

– Quality Assurance: Branch connection fittings and welds undergo thorough examination and testing, with specific requirements for record-keeping.

Understanding and implementing these standards not only ensures compliance but also fosters a culture of safety and reliability in engineering practices. Stay informed, stay safe!