The Bourdon pressure gauge is a mechanical device used to measure pressure in various applications. It was invented by French engineer Eugène Bourdon in the mid-19th century and has since become one of the most common and widely used pressure measuring instruments.

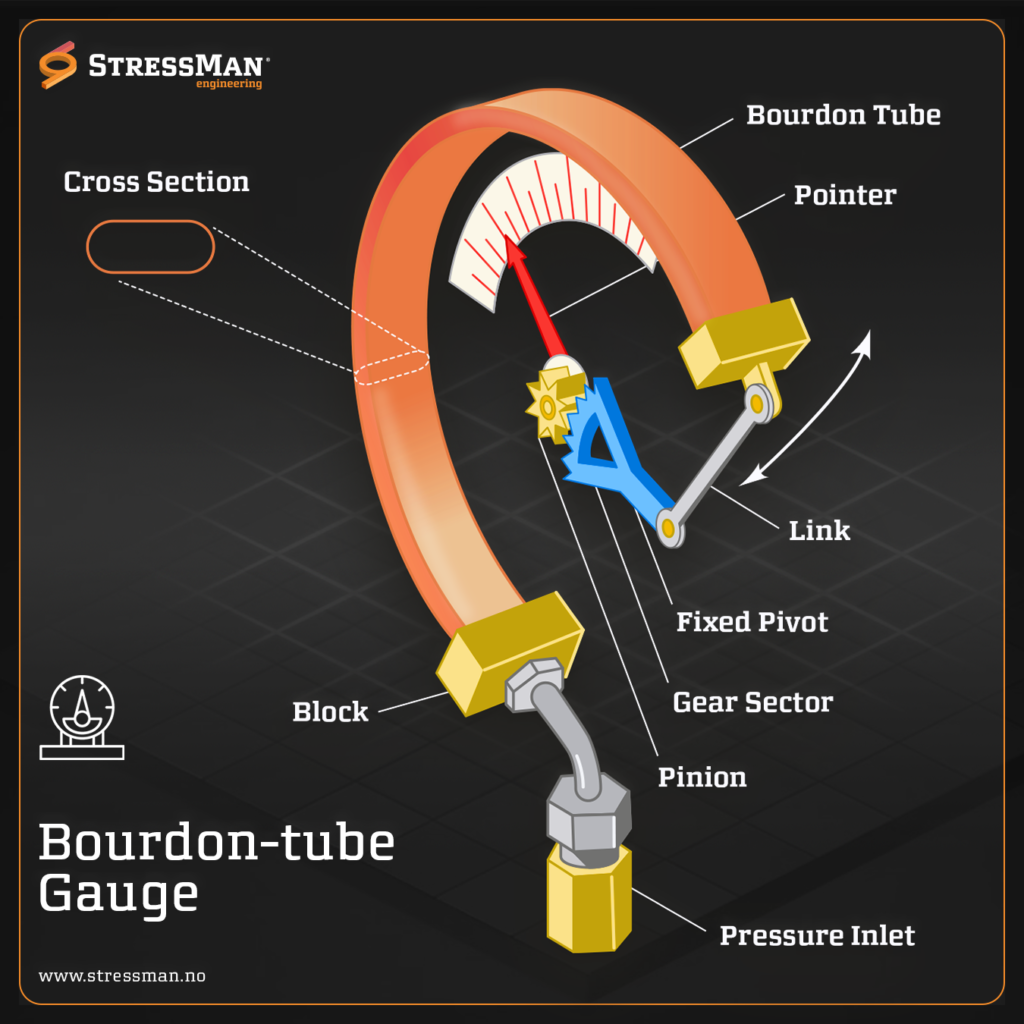

The basic design of a Bourdon pressure gauge consists of a curved tube, usually made of brass or stainless steel, which is closed at one end and connected to the pressure source at the other end. The tube is typically shaped like a flattened oval or a “C” shape, known as a Bourdon tube.

When pressure is applied to the open end of the Bourdon tube, it tends to straighten out due to the internal pressure. This causes the free end of the tube to move, which is connected to a mechanical linkage that drives a pointer on a circular dial. The movement of the pointer indicates the pressure being measured.

The Bourdon tube is carefully calibrated to provide accurate pressure readings within a certain range. Different Bourdon tube designs are available to handle different pressure ranges and fluid types. Some variations include spiral-wound Bourdon tubes for high-pressure applications or coiled Bourdon tubes for low-pressure measurements.

Bourdon pressure gauges are commonly used in various industries, including oil and gas, chemical processing, power generation, HVAC systems, and many others. They are known for their simplicity, durability, and relatively low cost compared to other pressure measurement technologies.

It’s worth noting that modern pressure measurement techniques, such as electronic pressure sensors and transducers, have gained popularity due to their higher accuracy, digital output, and compatibility with automation systems. However, Bourdon pressure gauges remain widely used and continue to be relied upon in many applications where their mechanical simplicity and reliability are advantageous.