In this article, the second moment of area of the rectangular hollow section will be compared (with and without rounded edges). This will be done by plotting the change in the second moment of the area by varying the thickness while keeping the section size constant, and by varying the section size while the thickness is constant.

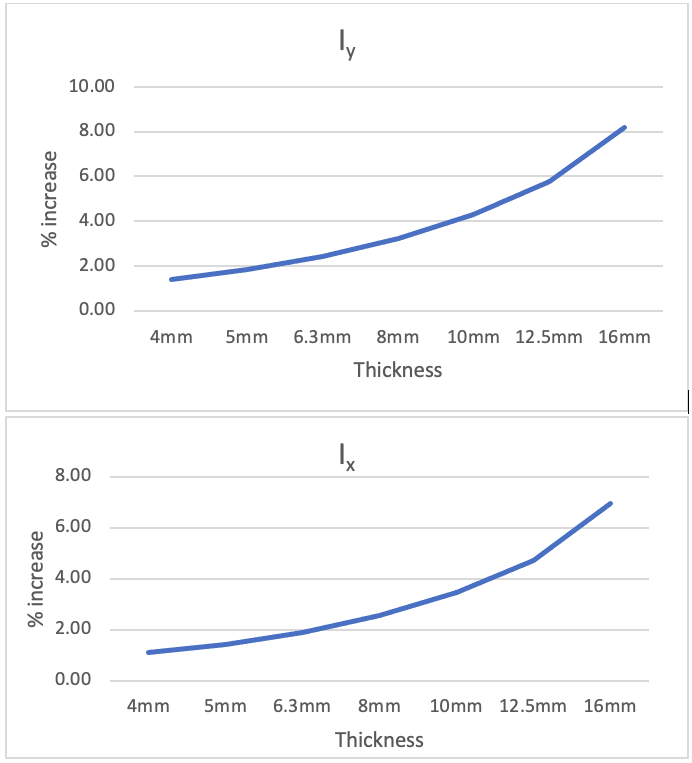

For the case with the varying thickness the section size chosen is 200mm x 100mm. The graphs below show the percentage increase in the second moment of area.

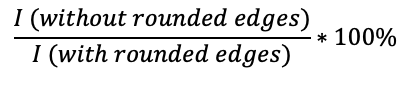

The graphs present in this article shows the percentage increase in the second moment of area;

The profiles without the rounded edges becomes increasingly stronger as the thickness increases.

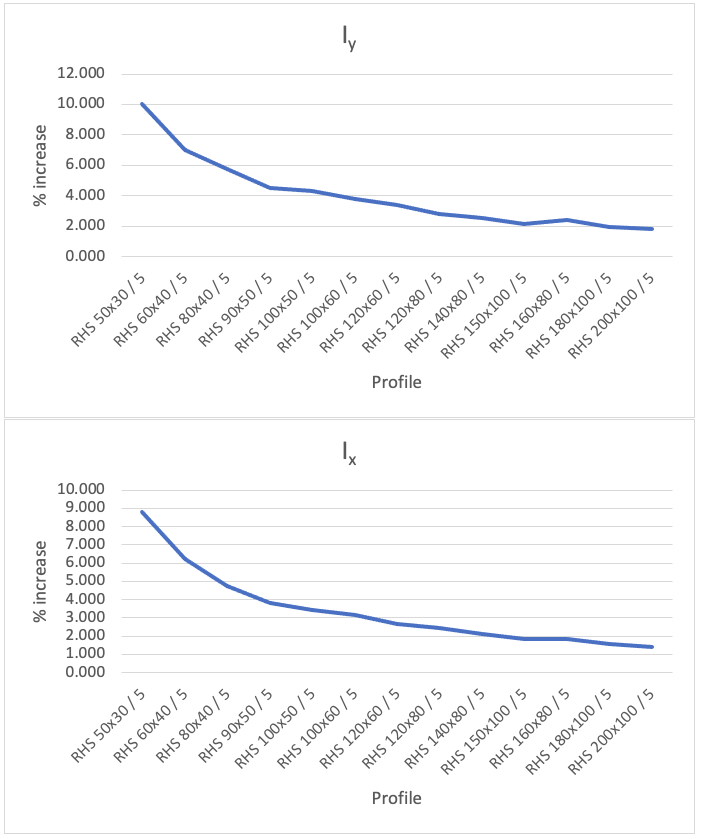

In the case with varying section size and constant thickness, a thickness of 5mm was chosen. The results are displayed in the graphs below.

As the section size increases the percentage increase in the second moment of area for the non-rounded profiles decreases.

The benefits of removing the rounded edges of the hollow profiles include:

-Easier generation of contacts

-Fewer faces

-Fewer nodes and elements, reducing run time

In conclusion, one should always keep in mind that the strength of the profile increases when removing the rounded edges. This is especially important in cases where the thickness is large or when dealing with small profiles where the thickness is large compared to the height and width of the profile.