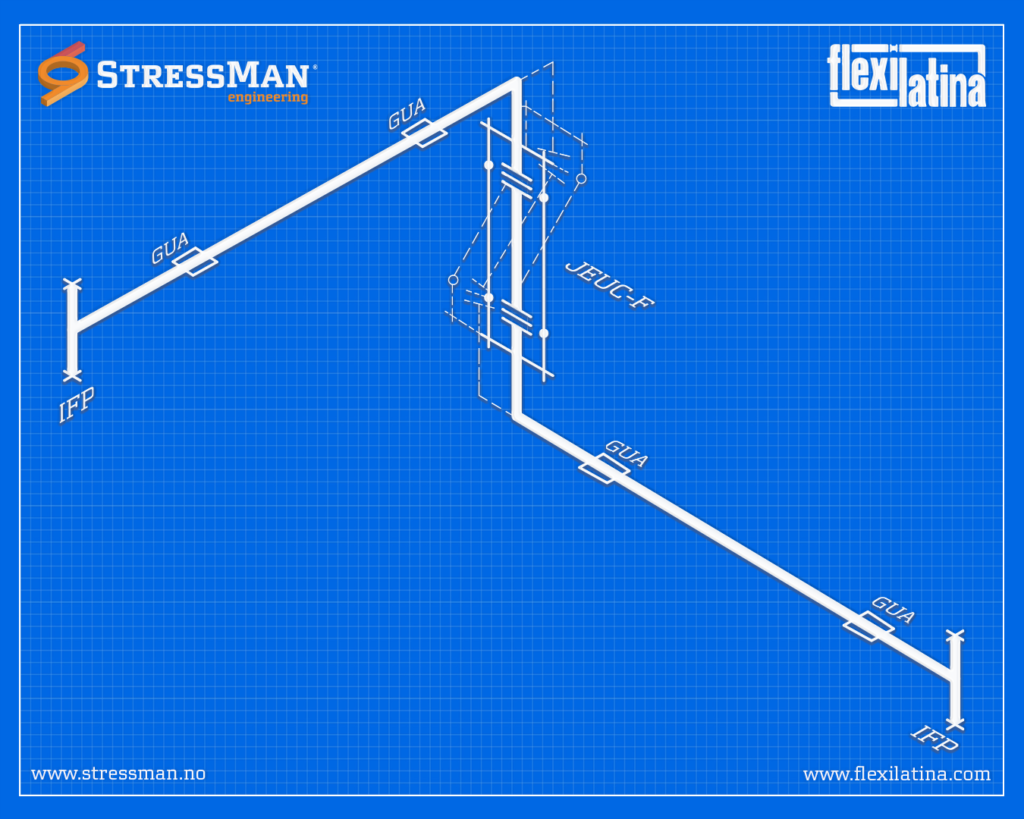

The double gimbal expansion joint is a flexible accessory designed to absorb lateral movements in pipes caused by thermal expansion resulting from temperature variations. This joint design absorbs lateral movements in one or two planes. This type of construction can only absorb the axial expansion of the joint itself.

The main advantage of double gimbal expansion joints over the typical universal tied expansion joints is in the operating pressures, which can be significantly higher for the former type.

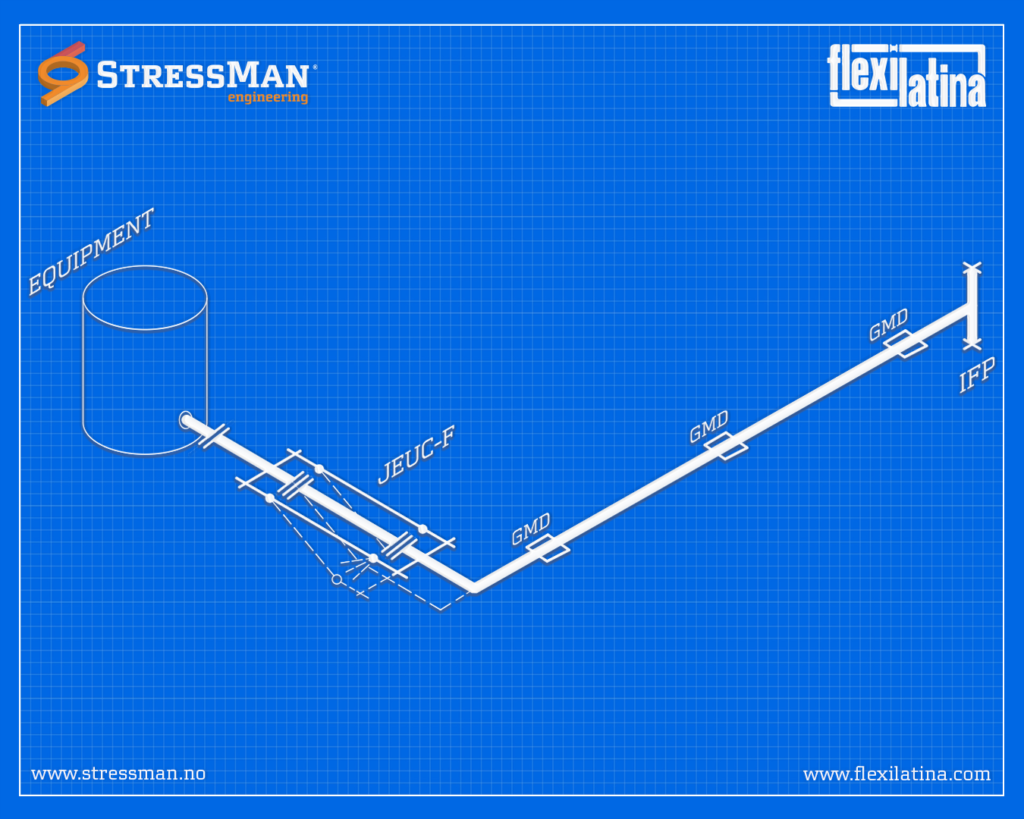

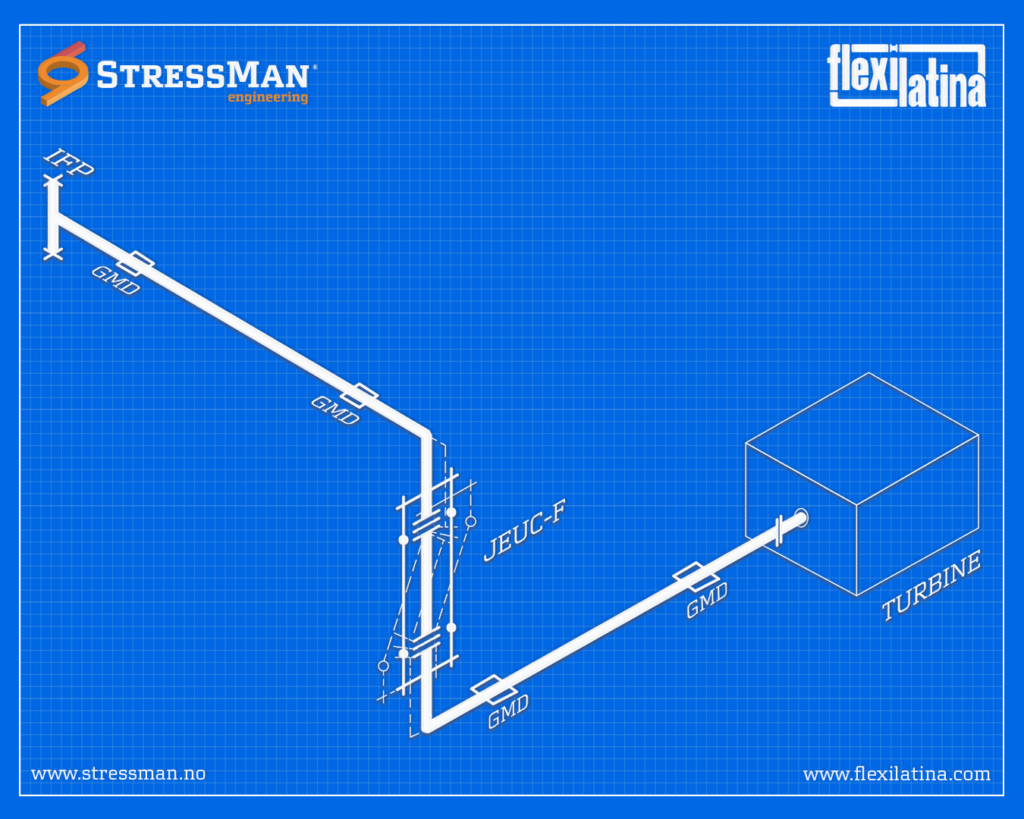

The typical mounting of this joint is in a piping system with 90° geometry, coplanar or biplanar. Its external structure contains the pressure reaction force generated by flexible bellows subjected to internal pressure. They also prevent axial movement from being absorbed by the joint.

DESIGN

The double gimbal expansion joints are made up of two bellows made of 300 series stainless steel, calculated under the rules of the EJMA (Expansion Joint Manufacturers Association) standard and according to ASME SECTION VIII (American Society of Mechanical Engineers), joined by an intermediate tube and structure with double hinges at the ends of the joint.

TYPICAL MOUNTING DIAGRAM

Double gimbal expansion joints are manufactured with external accessories designed to take the pressure thrust force and therefore contain this force internally, without transmitting it to the piping or equipment supports. Its length and the number of convolutions depend on the amount of lateral movement that needs to be absorbed by the joint.

Flexilatina de Colombia manufactures double gimbal expansion joints to absorb lateral movements of 50, 100, and 150 mm, with helpful life cycles greater than 1000.

ALLOWED MOVEMENTS

Each of the bellows of a double gimbal expansion joint has an angular movement capacity whose maximum value is 10º depending on the diameter and working pressure of the joint.

The combination of the angular movement of the two bellows allows a lateral movement of the joint. The allowed lateral displacement (Y) depends on the installation distance (Lu) between the two bellows and the maximum angle allowed.

DESIGN FEATURES

Maximum pressure: up to 300 psi (standard) or 600 psi (on request, at temperatures up to 1020°F (550°C)). Maximum temperature: up to 1650°F (900°C). Temperature and pressure are inversely proportional, the higher the working temperature, the lower the operating pressure.

MATERIALS

The determination of the manufacturing materials of the double gimbal expansion joints depends on factors such as the fluid to be handled, the operating temperature, its mechanical characteristics, etc.

APPLICATIONS

Piping systems that transport fluids at high temperatures: steam, hot air, hot water, thermal oil, chemical products compatible with the material of the expansion joint, etc.

For special applications, do not hesitate to contact Juan Manuel Mendez Franco.

Relax, let us handle your stress!