Orifice Plates: Precision in Flow Measurement

Orifice plates adhering to the global standard ISO 5167-2 are essential tools in process industries for measuring fluid flow in pipelines.

But how do they work, and what types are available?

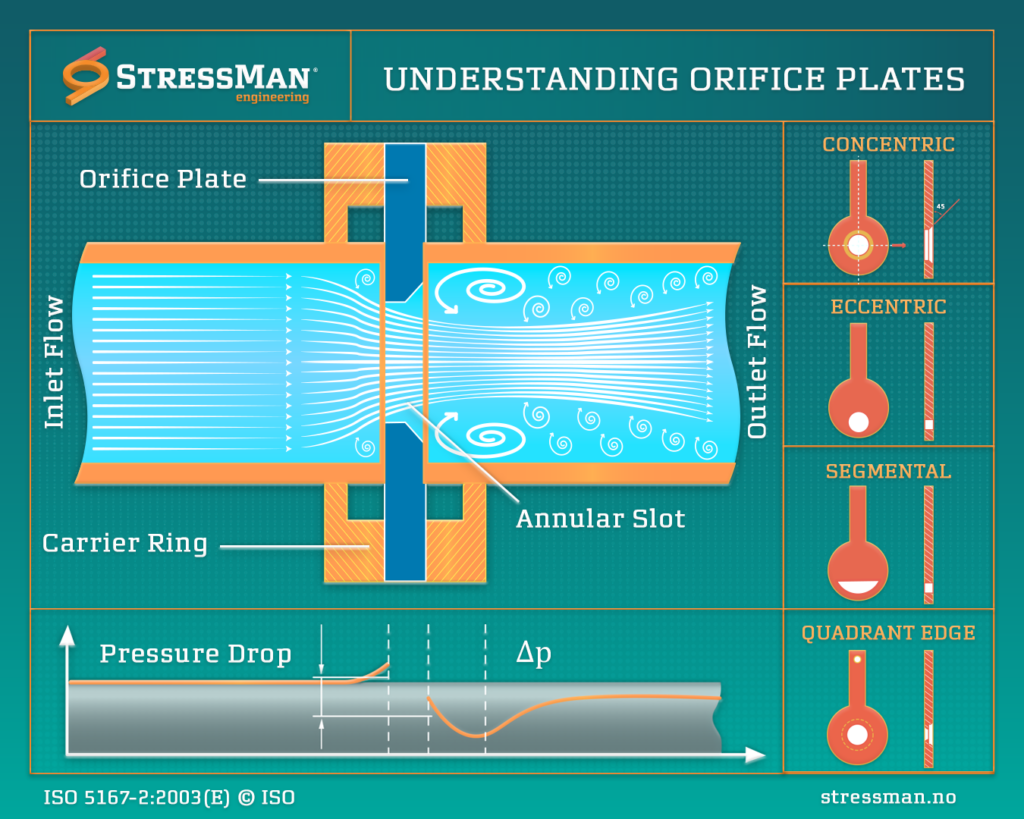

An orifice plate, a simple plate with a hole, is placed into a pipe. As the fluid passes through the constriction, it causes a pressure difference directly proportional to the flow velocity. Measuring this pressure difference and applying the Bernoulli principle reveals the flow rate!

Here are the four primary types of orifice plates:

1️⃣ Concentric: The most common design, with a central hole, suitable for clean fluids and versatile in most applications.

2️⃣ Eccentric: Designed for slurry or fluids with solid content, with an off-center hole to allow solid particles to pass and reduce wear and tear.

3️⃣ Segmental: Similar to eccentric in its application, it features a semi-circular opening, ideal for fluids with suspended solids as it allows solid particles to pass easily.

4️⃣ Quadrant Edge: Has a rounded edge around the hole, maintaining a constant discharge coefficient for highly viscous fluids and reducing wear.

Benefits and Considerations:

Orifice plates are simple, reliable, and cost-effective, providing easy installation and maintenance for a variety of fluids at different flow rates.

However, they do create a pressure drop, leading to energy loss, and are not ideal for applications with a wide range of flow rates. Precise installation and selection are crucial for accuracy.

Moreover, they require certain installation layout (straight pipe lengths) in order to guarantee measurement accuracy, which may be difficult to achieve.