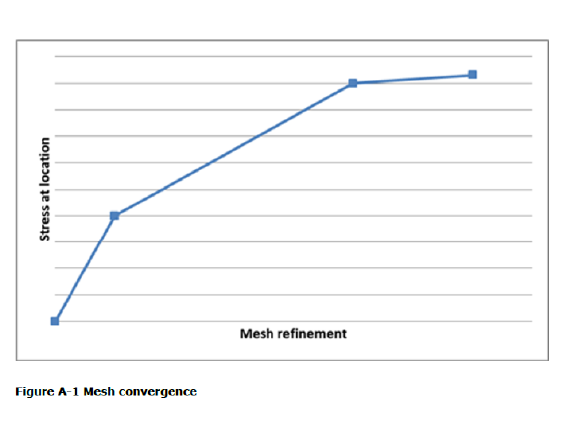

- Does not give consequent results

- Can easily be manipulated without breaking any code rules

- In several cases give confidence to bad mesh and bad results

- Adds 0 value and increase runtime

- Favorites bad engineering by Lower runtime and better results

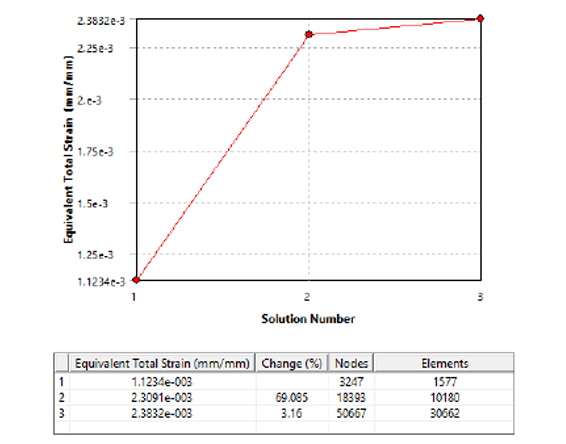

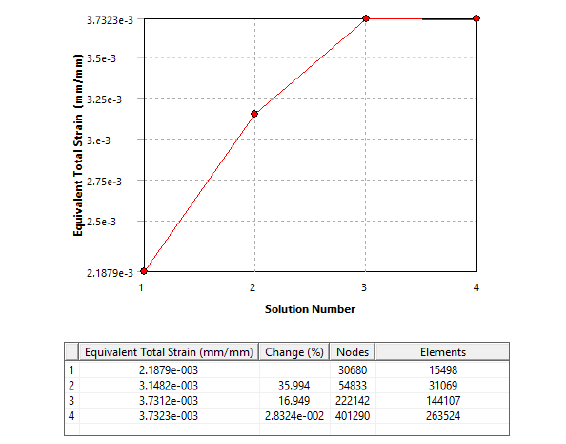

Mesh convergence setup from the code:

Non-linear Analysis:

A mesh convergence is considered reached with a convergence error of 5% on the total strain when a halving of the local element size is applied (ref. DNVGL-RP-F112 Appendix A1.1).

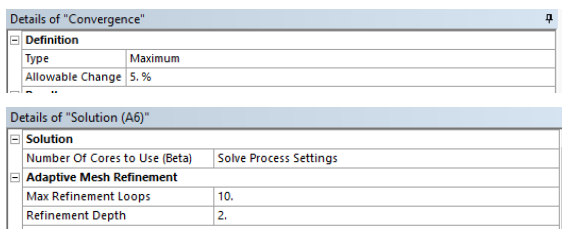

ANSYS Setup:

Refinement Depth of 2 equals halving of the element size.

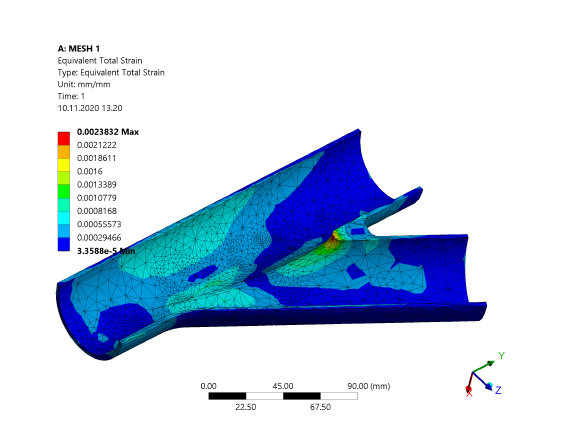

Start Mesh 1

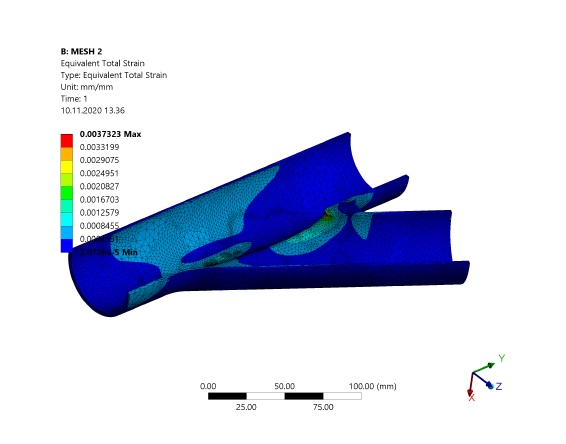

Start Mesh 2

End Mesh 1

End Mesh 2

Convergence History

Final strain value 2.3832e-003

Convergence History

Final strain value 3.7323e-003

57% Calculation error between 1 and 2, but both converged in accordance with DNVGL – RP – F112

What do you do?

•Use common engineering sense

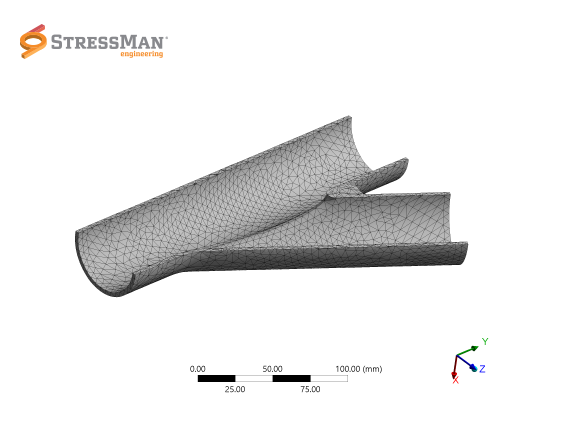

•Ensure that the MESH captures discontinuities

•Run some test and look for a change in results with different MESH

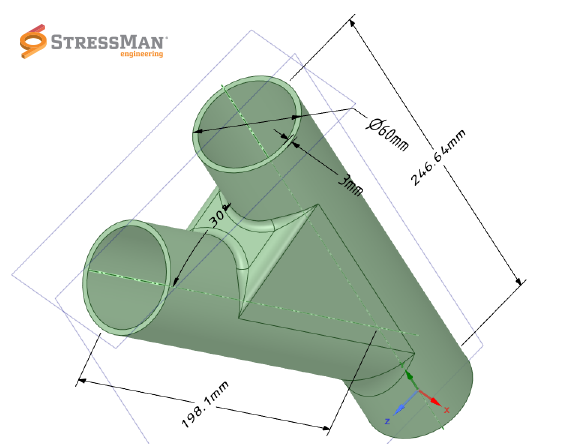

•For piping it is often a good start to have 3 elements across wall thickness and a mesh size of OD X 0.12

Example: This gives a 6” pipe a mesh of 20mm

Example: This gives a 6” pipe a mesh of 20mm

•Be critical when evaluating results