Team Stressman has over the years been chosen to perform flexibility calculations of fast-track subsea manifolds for TechnipFMC.

Our responsibility was to verify the structural integrity of the piping and piping components of the subsea manifolds. Subsea piping made of super duplex is exposed to hydrogen induced stress cracking (HISC). This complicates the pipe stress analyses, as in addition to checking it against ASME B31.8 Chapter VIII, all piping and components should also be checked against DNV-RP-F112.

Due to the high pressures ranging from 345bar to 690bar and HISC, many of the custom piping components had to be specially designed and calculated with elastic-plastic FEA. The residual stresses from hydrostatic testing was considered.

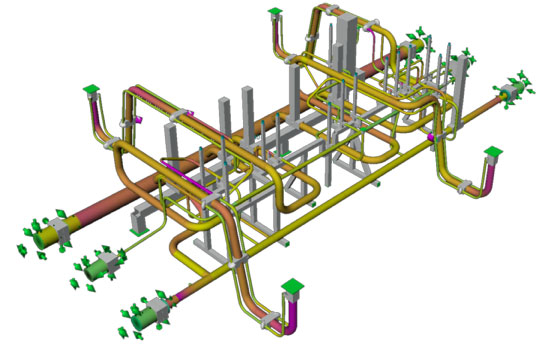

As the example, the Fram North manifold, below shows, the headers are connected to flexible flowloops that goes out to the Christmas trees. The reason for the great flexibility is the fact that it will not align perfectly with each other. Therefore, the flowloops needs flexibility to connect.