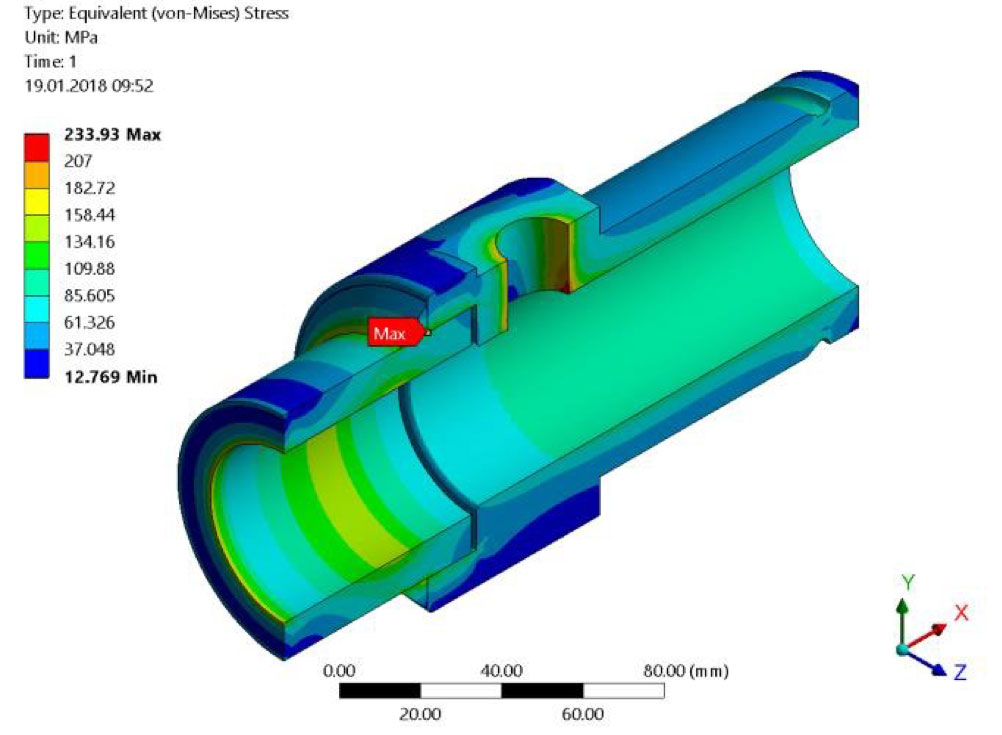

The aim of this project was to evaluate the stresses in an adaptor fitting made of stainless steel 316L. The stresses in the threads were calculated based on hand calculations. The stresses in the fitting was calculated based on finite element analyses (FEA).

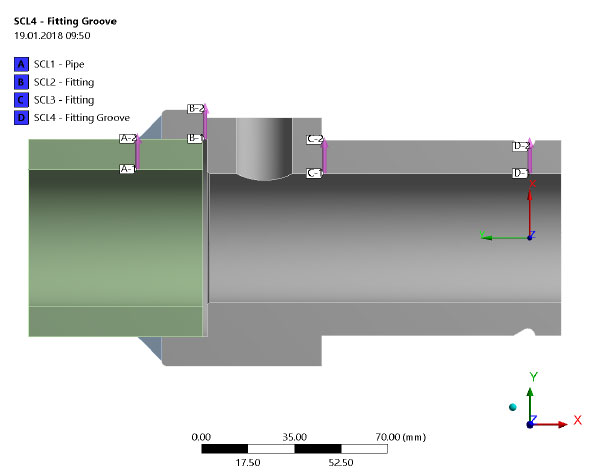

SCLs are drawn through the areas with the highest stresses. Several locations for the SCLs was extracted and the stresses for these areas was linearized. The membrane and membrane + bending stresses was conservatively classed as primary stresses. Since the original design code was ASME B31.3, the allowable stress from ASME B31.3 was used together with the methodology of ASME VIII division 2 section 5.