Introduction:

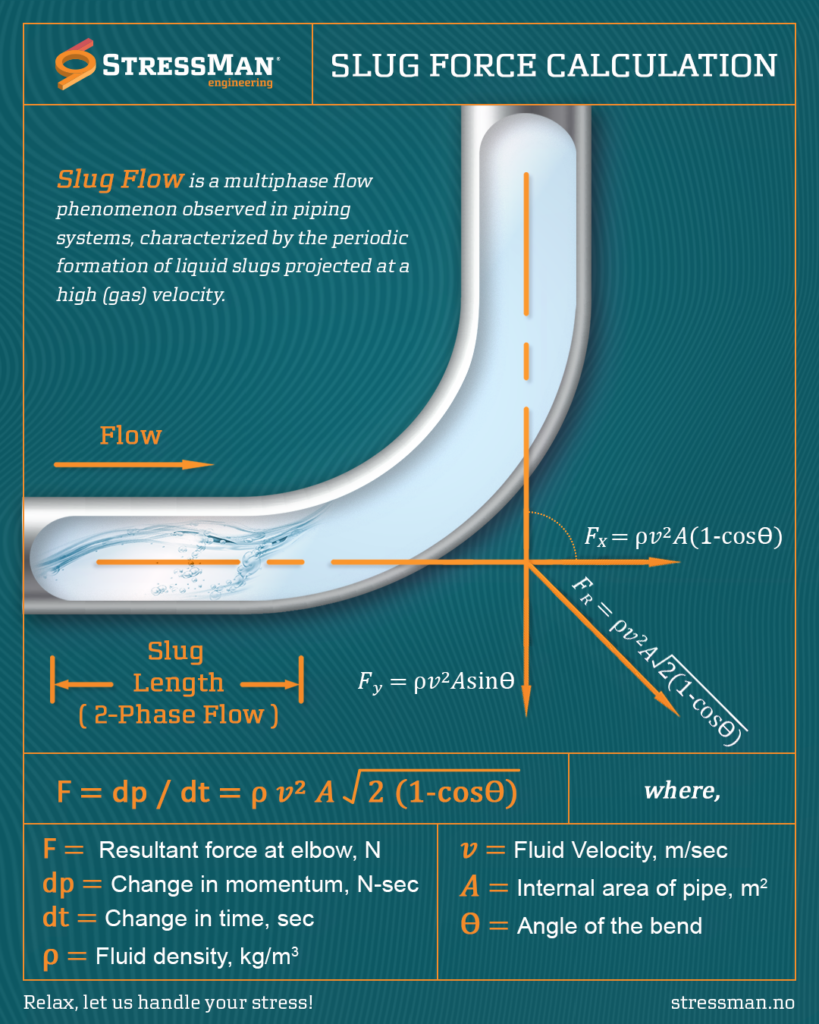

Slug flow is a multiphase flow phenomenon observed in piping systems, characterized by the periodic formation of liquid slugs projected at a high (gas) velocity. This phenomenon can lead to dynamic fluid forces due to changes in momentum, inducing vibrations that may result in structural damage.

To mitigate the risks associated with slug flow, several preventive measures can be implemented, such as:

1. Pipe Configuration:

– Design the piping configuration to protect against slug flow, particularly in areas where liquid can collect (e.g., pockets).

2. Low Point Drains, Traps or Bypass:

– Utilize drains, traps, or bypasses at low points to prevent liquid collection.

3. Insulation Check:

– Regularly check insulation to minimize condensate formation.

4. Complete Draining:

– Design equipment and piping to allow complete draining and eliminate pockets that can trap liquid.

5. Inclusion of Traps and Valves in Maintenance Programs:

– Include traps, pressure control valves, safety valves, and rupture disks in preventive maintenance programs.

6. Review of Abandoned Equipment:

– Conduct a review of abandoned in-place equipment and piping to identify potential sources of liquid buildup.

7. Material Selection:

– Select materials with reasonable tensile strength to resist dynamic transients and impact loads (e.g., avoid using cast iron).

8. Design of Supports:

– Ensure proper design of supports for transient performance.

9. Use Slug Catchers:

– Design and use slug catchers for collecting slugs at the pipeline outlet.