A Venturi flowmeter is a type of flow measurement device that operates based on the principle of Bernoulli’s equation. It is designed to measure the flow rate of a fluid (liquid or gas) through a pipe by creating a constriction in the flow path.

Here’s a brief description of how a Venturi flowmeter works:

Constriction:

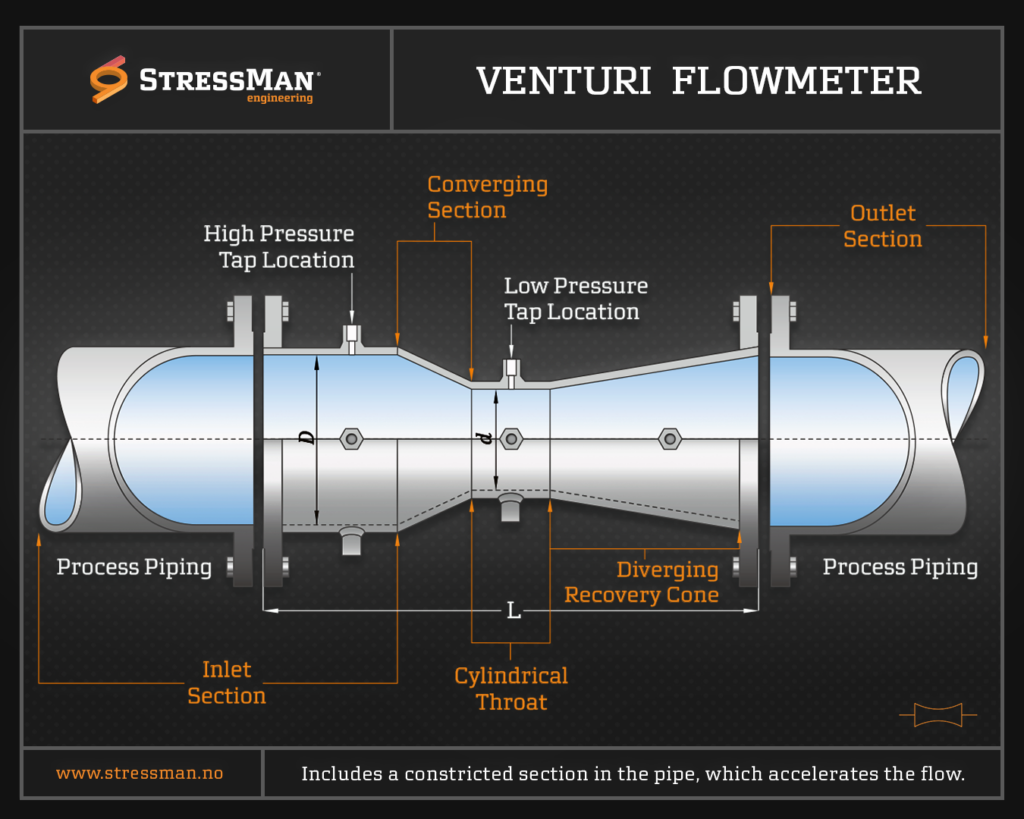

A Venturi flowmeter consists of a pipe with a gradually narrowing section in the middle, called the Venturi tube or throat. The narrowing section reduces the cross-sectional area of the pipe, causing the fluid to accelerate as it passes through this section.

Pressure Difference:

As the fluid accelerates in the Venturi tube, its velocity increases, and according to Bernoulli’s equation, the pressure decreases. This decrease in pressure is proportional to the square of the fluid velocity.

Pressure Taps:

Pressure taps are strategically placed upstream and downstream of the Venturi tube. These taps allow for the measurement of the pressure differential across the Venturi meter.

Pressure Measurement:

The pressure difference between the two taps is measured using pressure sensors (typically pressure transducers or manometers). This pressure difference is directly related to the flow rate of the fluid.

Calculation:

By knowing the pressure drop and the characteristics of the Venturi tube (e.g., throat diameter and pipe diameter), it’s possible to calculate the flow rate of the fluid using specific equations or calibration curves provided by the manufacturer.

Advantages of Venturi Flowmeters:

– Accurate and reliable flow measurement.

– Minimal pressure loss compared to some other flow measurement devices like orifice plates.

– Suitable for a wide range of flow rates and fluid types.

– Less susceptible to wear and erosion compared to other flow measurement devices.

Venturi flowmeters are commonly used in various industries, including chemical processing, water treatment, oil and gas, and HVAC systems, where precise flow measurement is required.

Please note that while Venturi flowmeters are highly accurate, their installation and calibration should be performed carefully to ensure accurate measurements.

Additionally, the pressure taps and sensors used for measurement must be maintained and calibrated regularly to maintain accuracy.